Product Library & Air Motor Resources

Air Motor Catalogs & Line Cards

Pneumotor Products

Pneumotor Test Equipment

GLOBE Product Overview

GLOBE General Catalog

GLOBE Vane Air Motors

Vane Air Motors Catalog

Non Lubricated Vane Air Motors

Geared Vane Air Motors PFG Series

Vane Air Motor Brakes

GLOBE Piston Air Motors

Piston Air Motors Catalog

GLOBE Small / Compact Air Motors

Compact Vane Air Motors - Archimedes

Compact Vane Air Motors - M53 Series

Compact Vane Air Motors - M400 Series

Compact Piston Air Motors

Silencers & Noise Reduction

GLOBE High Noise Reduction Silencer

GLOBE High Flow Silencer

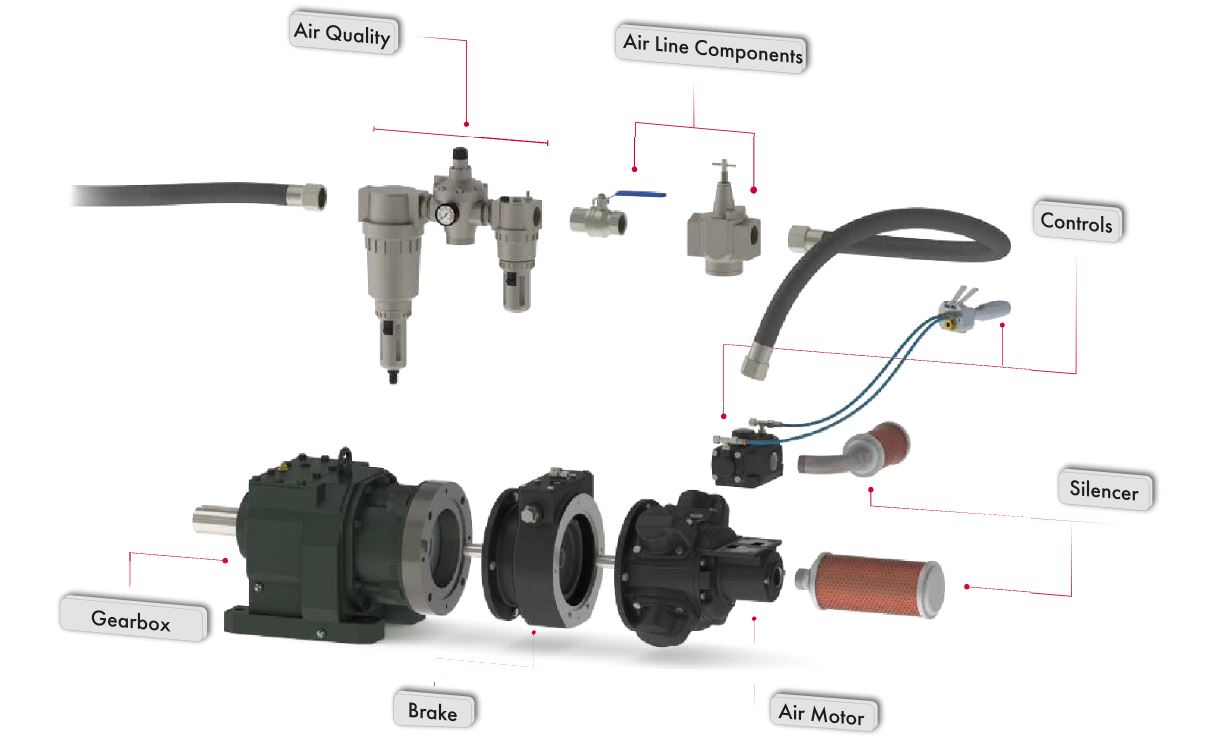

(ref. air motor resource)

The illustration above demonstrates a typical pneumatic assembly. This illustration is for general reference, it may not be applicable to your application. For specific product information, please see our 'products' section. Downloadable material is contained within the 'literature' tab on this page. (ref. air motor resource)

Vane Air Motors

The vane air motors are the most widely used design of air motors. They are available in a broad range of power and can operate in any position. The vane air motors prove themselves to be a much lighter and more compact compared to piston air motors of similar power. A combination of a Globe vane air motor with a large variety of gearboxes is possible when lower speed and/ or higher torque is demanded for the application.

The most typical vane air motor applications include:

- Mixing equipment

- Ventilators

- Hoists

- Winches

- Pump drives

- Conveyor belts

- Turntables

- Packing machines

- After coolers

Compact Vane Air Motors

The compact vane air motors are motors that have incorporated reduction units. Due to the wide range of gear ratios the compact vane air motors are suitable in many different applications. The compact vane air motors are known for delivering very high speed and very high torque compared to the compact build of the motor.

The most typical compact vane air motor applications include:

- Handheld applications

- Pipe cleaners

- Conveyors in the food industry

Piston Air Motors

The Globe piston air motors are heavy duty air motors. This radial piston air motor combines a large variable speed with high power and torque. The motors have either four or five pistons with oil bath lubrication and their design allows them to deliver the highest power in air motors. A combination of a Globe piston air motor with a large variety of gearboxes is possible when lower speed and/ or higher torque is demanded for the application.

The most typical vane air motor applications include:

- Winches

- Offshore and other heavy duty applications

Compact Piston Air Motors

The Globe compact piston air motors are used in numerous applications. Due to its unique design the compact piston air motor are most suitable for light and medium duties at low speed operations. A combination of a Globe compact piston air motor with a large variety of gearboxes is possible when even lower speed and/ or higher torque is demanded for the application.

The most typical compact piston motor applications include:

- Mixing applications

- Winding equipment

- Conveyor belts

- Hose reels

- Turntables

- Packaging machines

- Cap screwing machines

(ref. air motor resource)

How to Select the Right Air Motor

- Determine the required:

Torque [ft lb]

rotation speed [RPM]

Power [HP]

If one of the 3 parameters isn’t available,,, calculate it:

HP = T x RPM / 5252

T = HP x 5252 / RPM

RPM = HP x 5252 / T

- Determine the available airline pressure. (If unknown, calculate with 90 psi)

- Does the motor need to start under load or not?

Examples of applications starting under load: hoist, winch and conveyor belt.

Examples of applications starting with no load: fans, pumps and mixers.

Starting under load: calculate with the minimal starting torque to insure sufficient torque at start-up

- Select a gearbox if necessary

Example:

Required drive torque: 150 ft lb

Available torque air motor: 10 ft lb

Efficiency of gearbox:

Spur gears: 90 – 95%

Worm gears: 10 – 60%

Reduction is: 150/(10 x 0.9) = 16.7:1 ratio

(ref. air motor resource)

1 - General Troubleshooting Guide

Common Problem | ||||

|---|---|---|---|---|

2 - Fault Finding - RM Style Piston Motors

- The RM series motors are designed to perform at their rated capacities for long periods of time. Faults can develop for the following reasons:

(A) Lack of lubrication. This will result into rapid wear, internal seizure, loss of power or excessive air leakage.

(B) Faults in the air supply system:

- Failure to remove the plastic protective dust caps

- Insufficient air pressure at the motor caused by:

(a) Supply pipeline or valve too small

(b) If the exhaust is piped away excessive back pressure due to small bore pipes

(c) Compressor of insufficient capacity

(d) Clogged air line filter

(e) The air pressure should remain at the required pressure when the motor is operating at full potential. If the air pressure reduces considerably from the stationary to the rotating conditions, then the supply line or the compressed air available is inadequate for the service operation of the motor.

The motor should always be supplied with clean moisture free and lubricated air. The better the quality of the air the less attention will be required to the motor unit. Air quality should meet ISO 8573-1:2010 class 4 for solid particles and ISO 8473- 1:2010 class 3 for water.

Copies of Globe Air Motor(s) maintenance manuals are available on request. Please contact us.

(ref. air motor resource)